Our production facility has all

Your equipment needs

We are here to help support your next project

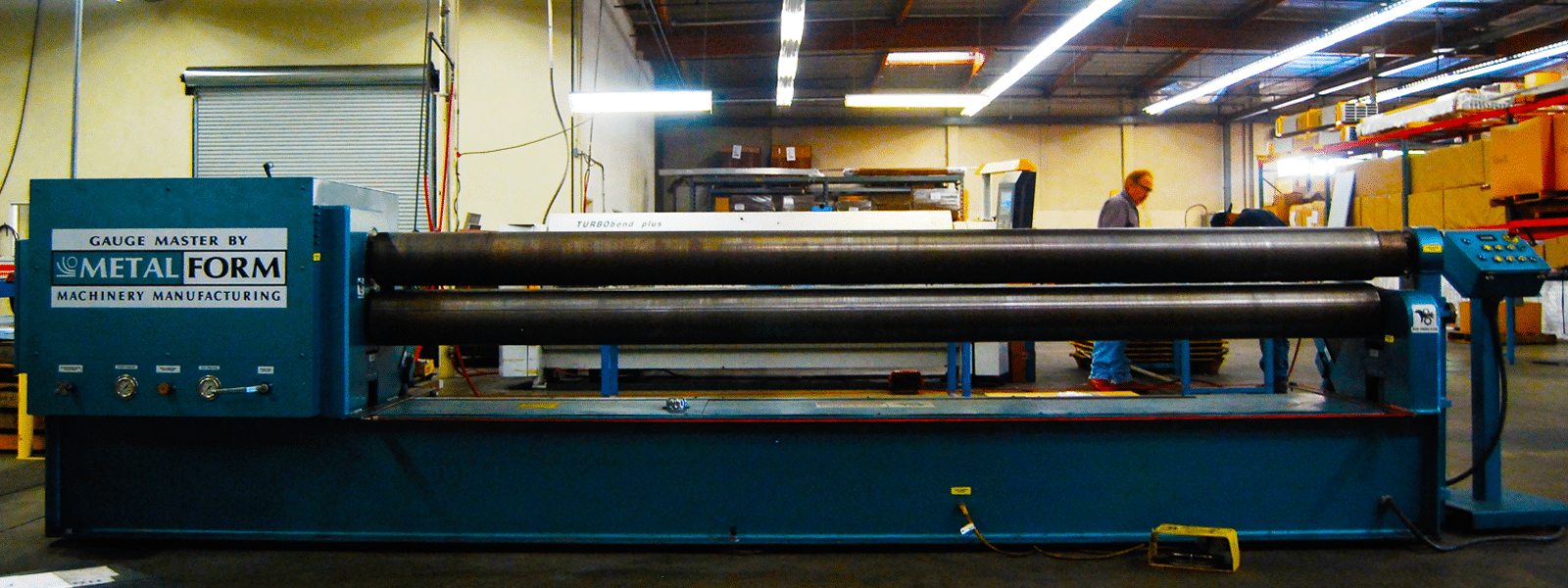

Adams Campbell’s over 80,000 square foot state-of-the art production facility consists of some of the industry’s most recognizable and high tech equipment. We offer an assortment of prototype, medium run, and production capable equipment, such as auto loading lasers, auto loading CNC lasers and turrets, punch presses up to 500 tons, CNC controlled press brakes, and various welding capabilities.

Let us be an extension of your business

We understand critical time-to-market issues and we also understand the expenses incurred in warehousing inventory. That’s why Adams Campbell provides true, just in- time manufacturing, so you can meet tight schedules while maximizing supply chain efficiencies. We’ll assist in cutting your inventory costs and help you solve overall production issues quickly and cost effectively.

What you need when you need it

What you need when you need it

Needing to do more with less, and do it faster, and having the ingenuity to find hidden assets that will enable you to get the most out of everything you have. You may unknowingly and inadvertently limit your opportunity and upside. Managers know they need to work smarter, not harder, but how? This is true for the organization, the people, and the business.

Committed to staying the best

Committed to staying the best

We have continuously invested in the latest technology such as lasers, CNC punch presses and brake presses to ensure we have the most cost effective solution to meet your design needs.

Key Equipment

We offer an assortment of prototype, medium run and production – capable equipment, such as auto loading CNC laser and turrets, punch presses up to 500 tons,

CNC controlled brake passes and several tig and mig welders. Our equipment allows you the flexibility to deep draw stainless to working on forming

up from sheet stock. With a 500 ton press we can deep draw sinks to various other requirements or form your part up from sheet stock.

With our CNC controlled lasers and turrets we can laser or punch your design into reality.

2 – Trumpf Lasers

Our two auto load lasers allow us to produce quick prototypes to running large production orders lights out.

4 – Amada CNC Turret Punching Cells

Our extensive tooling for our auto load CNC Turrets’ allows you to design counter bore, radius areas, emboss, lance form and other shapes into your parts to meet

your needs.

13 – Amada Brake Presses

Our extensive brake form tooling and number of brake presses

allows you to design different bend radius and know we will

be able to react quickly.

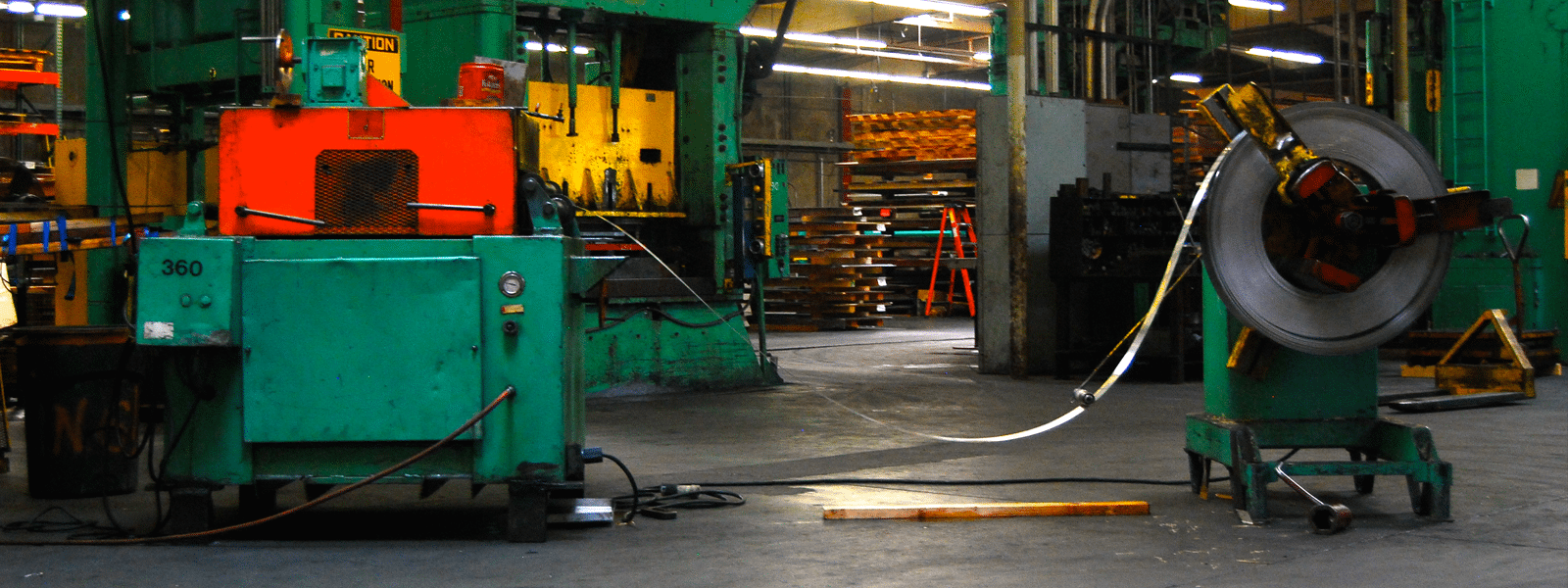

Deep Draw and Punch Presses

Our speciality of deep drawing stainless parts is second to no other company in Southern California.